production process

matcha

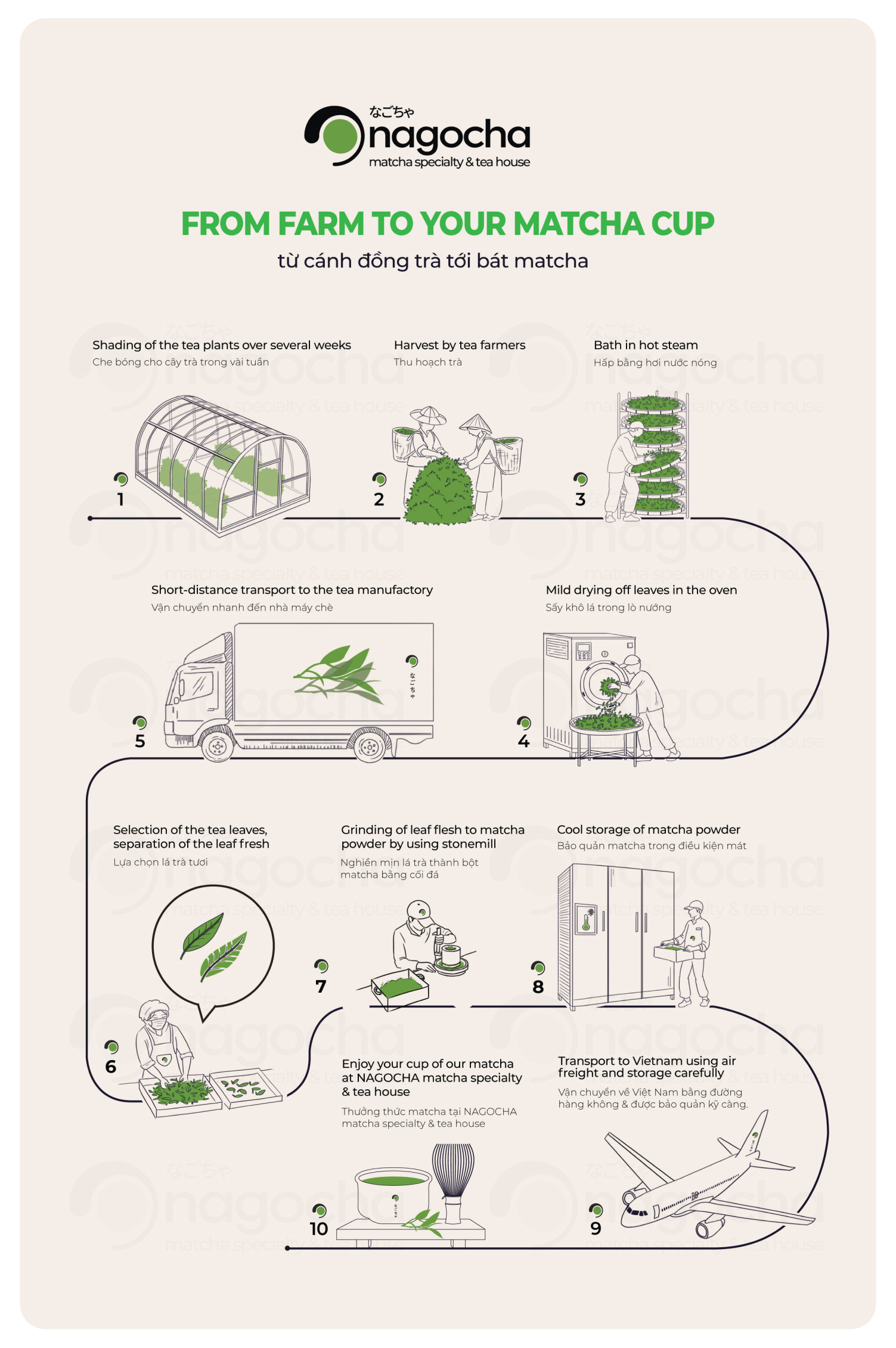

A step-by-step process of matcha production to help you better understand where it comes from and why it is more expensive than other green teas.

Available at 24A Tran Binh Trong st.,

Nha Trang, Vietnam

Matcha is a premium green tea powder that is grown and produced exclusively in Japan. It is known for its vibrant green color, intense umami flavor, and high nutritional value. In this article, we will take you through the step-by-step process of matcha production to help you better understand where it comes from and why it is more expensive than other green teas.

Step 1: Shade Grown

The first step in matcha production is the shading process. Tea farmers cover the tea plants with bamboo mats or rice straws mounted on top, protecting them from direct sunlight. This process lasts for approximately two to six weeks before harvest time. Shading is believed to increase the chlorophyll content in the leaves and force the antioxidants to rest on top outermost part of the leaves. Chlorophyll is what gives matcha its lush green color, while amino acids give it the intense umami flavor.

Step 2: Hand Picked

During the spring or mid-April to mid-May, the harvesters pick only the youngest and greenest tea leaves. The first harvest, called Hachijuhachiya, has the absolute finest quality compared to the second harvest that occurs 40-45 days later.

Step 3: Steamed and Air Dried

Once the leaves are harvested, they immediately undergo a steaming process that lasts for roughly 20 seconds. This is done to prevent the leaves from oxidizing, retain the vibrant green color, and maintain the nutritional components. The leaves are then passed through a blower to eliminate the moisture condensation, and the tea processors crush the dried tea leaves for easy sorting/de-stemming. The raw material produced after this stage is referred to as tencha, which is the precursor of matcha powder.

Step 4: De-stemmed and Graded

Before the tea leaves are stone-ground into matcha powder, they are de-veined and de-stemmed to ensure only the finest leaves are grounded into matcha. Tea processors sort the leaves into containers according to color, texture, and aroma, and will add in hot water to the tencha to grade the quality of the tea. After grading, the tea undergoes proper labeling, and the processors store the teas in a refrigerated room where it can maintain its quality.

Step 5: Grounded into Matcha

The final step in the matcha production process is the grinding. Tea processors grind the tencha on a stone mill to achieve a fine, smooth powder texture and superior consistency. This process is what gives matcha its name, which literally means “ground tea.” Finally, the matcha tea powder undergoes vacuum packing and is then stored until it’s ready for shipping.

In conclusion, matcha production is not just a delicate task, but also an art of its own. Japanese tea farmers have been practicing these unique traditions for over 800 years to maintain the quality and authenticity of matcha. By understanding the matcha production process, you can better appreciate the hard work and dedication that goes into producing this special green tea powder.

SEEING IS BELIEVING

Ceremonial vs Culinary

WATCH TOGETHER

Why matcha is expensive?

AT CHAKOKORO NHA TRANG

Available Matcha Cultivars

GOKOU

VIEW DETAIL

GOKOU

ASAHI

VIEW DETAIL

ASAHI

SAMIDORI

VIEW DETAIL

SAMIDORI

OKUMIDORI

VIEW DETAIL